For the first two Weeks the veterans split off from the rest of the class to make a safety video for the rest of the class. The first few days we planned what we wanted in our video and created a shot list. On wednesday Dr. Neat introduced the wednesday challenge with the spaghetti bridge challenge. The challenge was we were divided into groups and had to make a bridge at least two feet long out of only twenty pieces of speghetti and wood glue. Your score was the weight your bridge held divided by the weight of your bridge. On the second thursday the JPL invention challenge was released and the veterans also spent some time on that. This year's challenge is to transport water in a cup two meters into a separate recepticle spilling as little water as possible and transporting a plastic goldfish.

2016 JPL Invention Challenge Rules

We finished the last of the filming for the safety video today and continued discussion of the JPL invention challenge. I started editing the video. We discussed the main restraints and a few basic concepts for the challenge. I don't remember much... sorry.

Today the veterans broke off again to talk more about the JPL invention challenge. We reviewed the rules more closely in order to figure out what restrictions there are on our concepts. We then completely disregarded those rules and just came up with as many concepts as we could. Our ideas include a car, an overhead crane, a slider and what we call the kevin arm which just flips the cup over. We also came up with the idea of a funnel that could be applied to any concept.

Today we did more work on our spaghetti bridge. I believe today we went with a simple design of gluing all the spaghetti together in one bundle. It didn't work very well but it gave us good information. In my position i provided help when needed and provided ideas to help them do better with their concepts.

Today we continued work on the JPL invention challenge as the veteran group. We got a better idea of the concepts. I created a powerpoint with a simple description and simple diagram of each concept so we could present them to the rest of the class and to Mr. Wilton. We also created a few concepts that broke the rules and weren't effective to try to teach the class what to look for in a design. The safety video was supposed to be done by tomorrow but due to shcoolwork constraints i haven't been able to finish it.

Today we explained the JPL invention challenge to the rest of the class in more detail and presented the presentation I made to them and Mr. Wilton. We had them ask questions and come up with suggestions for the concepts to get them thinking about the challenge. We got input from both Mr. WIlton and the class on our concepts.

Over the Weekend i was able to get a first copy of the video done and editied. On monday we discussed JPL invention challenge and we decided which ones had the most interest behind them. and depricated the ones with little interest or no interest.

Today my group glued up our final test bridge. Once again, like the first concept, it ended up twisting and buckling under very little weight.

Today was the last day to build your spaghetti bridge so that it could dry overnight. My group worked on the box design that followed the concept of a train bridge we found online. It was hard because we accidentally made the top and bottom first so it was hard to lift the top so that we could contruct the sides to hold it up, we used various objects of very similar height to hold up the top while we constructed the sides. Sme of the veterans also took a small amount of time to film one last clip we needed for the safety video. I then made the final edit that night and gave it to Mr. Miller the next day.

So this happened today... poor spacex. crazy rocket explosion. But we also did the bridge competition, my group came in fourth withh a ratio of 10.32. We were really happy about that because our previos best had been a 7. I was the photographer for the competition and have a lot of pictures i dont know what to do with. For being a team of all rookies we did really well and i was very happy with our preformance and how well we worked overall on the challenge. I then stayed up until 12:45 the next morning doing my website because i had been to busy to do it any other time.

After a great four day Weekend where i went to a dodger game and got a bad sunburn, I was kind of ready to get back to engineering, the outside doesnt like me... In class the newbies learned to do the wednesday challenge sheets and i followed along since this is my first year. I had already done mine for the spagheti bridge but i learned a few thhings i could change.

Today the veterans broke off while the others did wednesday challenge and we discussed our goals that we wanted. We created a rough calendar for the JPL invention challenge and we also created a list of requirements for all of the devices that we plan to build. We tried to be hopefully realistic with our dates and if we stay on schedule(not entirely likely) we will have a lot of time to test and tweak.

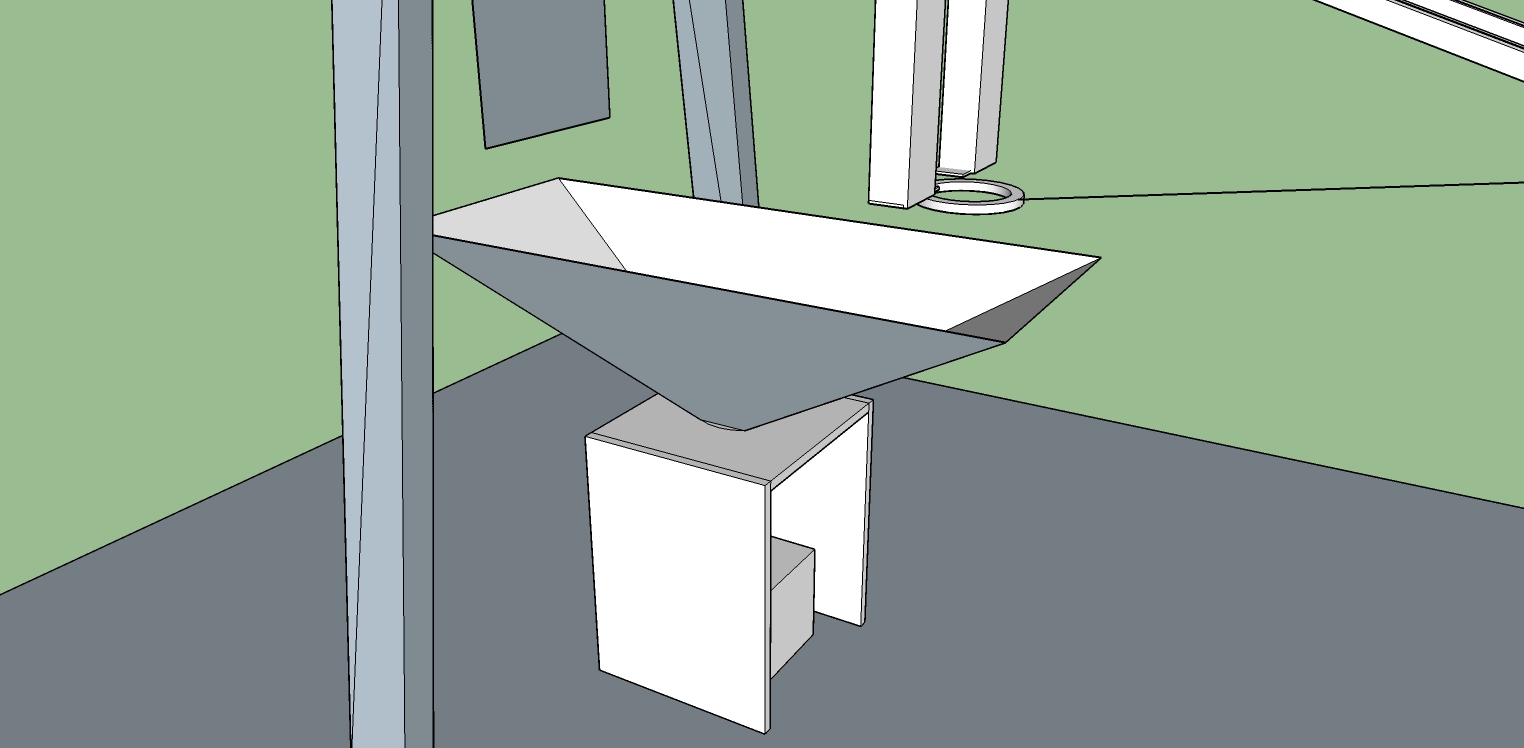

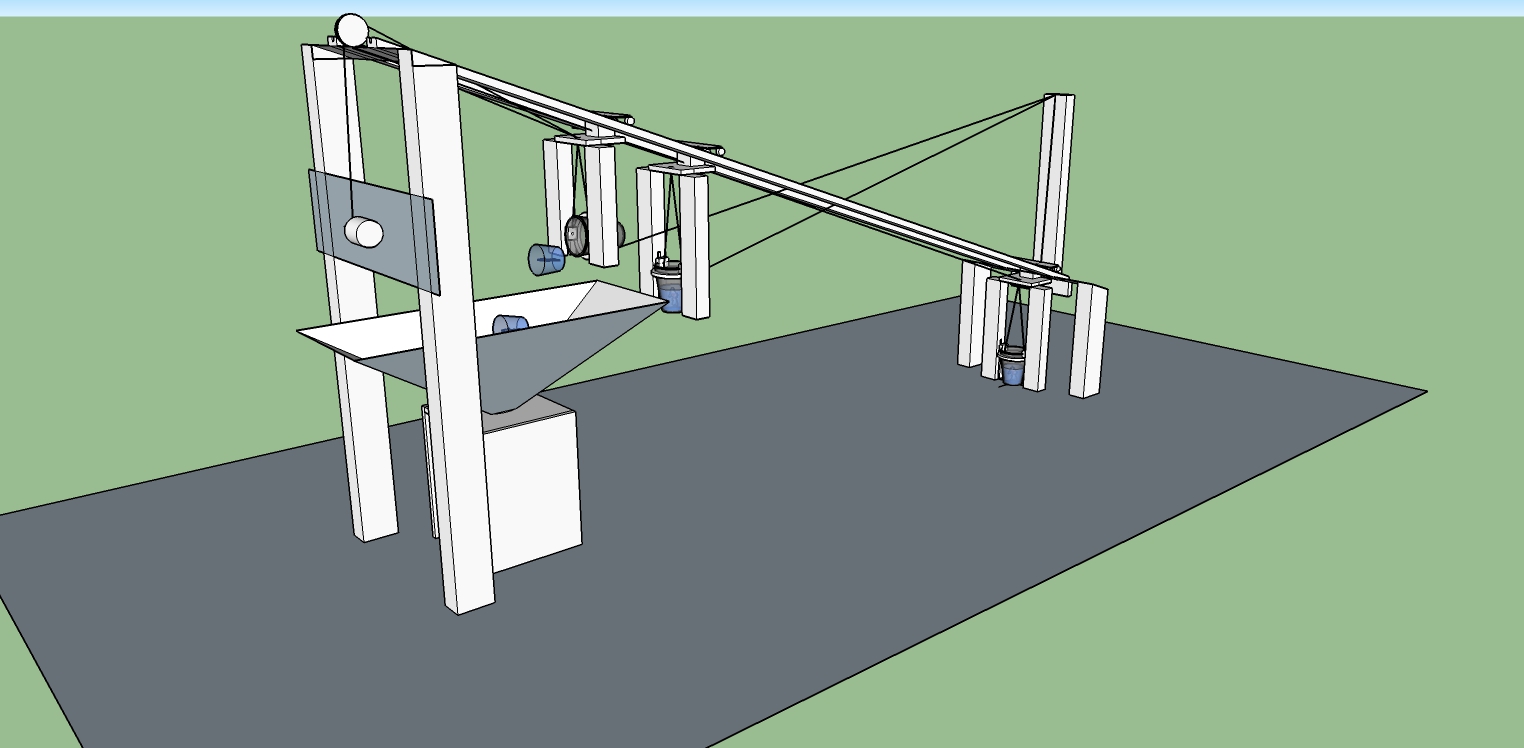

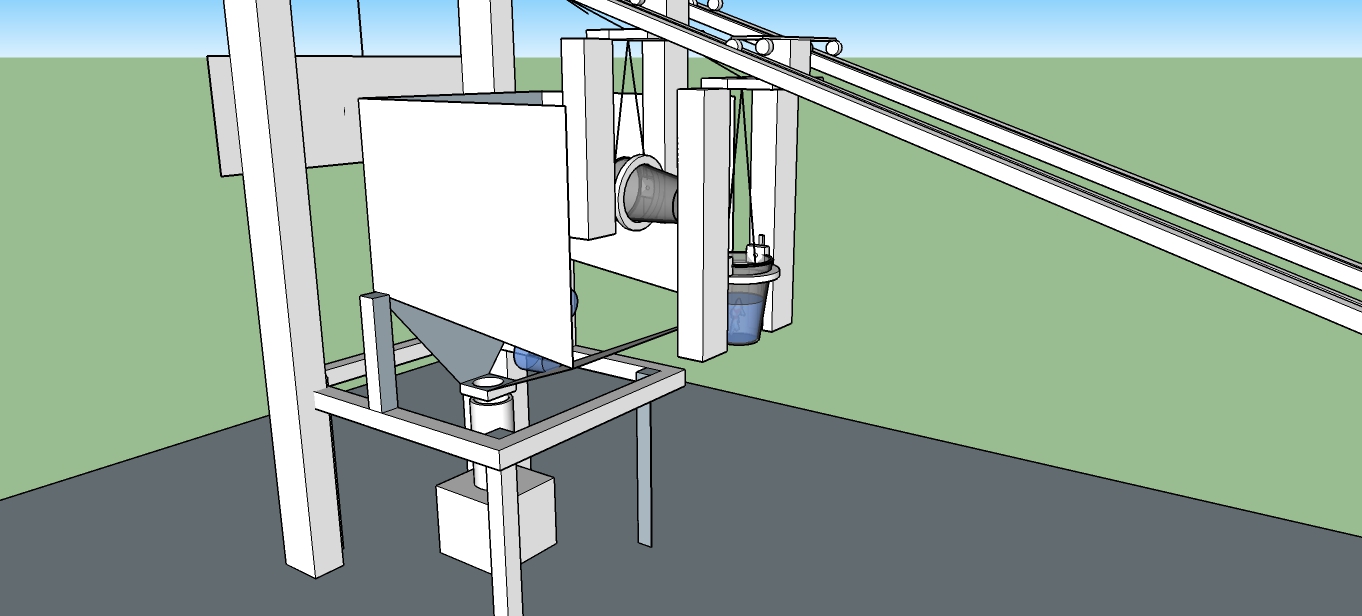

Today the veterans broke off again to discuss more about JPLIC. We originally were going to create more specific list of requirements for our four concepts but we decided that our comprehensive one did a good enough job. So then the veterans broke into groups of 2-4 for each concept and started to do a basic design. Cole and I are on the team that's working on the overhead crane concept. I started a basic sketchup of our design and tomorrow we will present what we have to Mr. Wilton and the rest of the class.

Today Mr. Wilton came in. The veterans presented to the class the list of requirements we came up with. Also, those of us with concept CADs presented those and we got comments from both the class and Dr. Neat and Mr. Wilton. Initially i had planned to use the inertia of the cup to help my design but Mr. wiilton pointed out thatt that would be unpredictable and unrealiable so I figured out a different way to tilt the cup. He also pointed out that to get over the top of the funnel it would be really helpful to have the track itself be at an incline to lift the cup. I will change the cad to accomodate those ideas.

Today the JPLIC group broke off and worked on their designs. Cole and I further refined my design. Kevin and I both created cad for a funnel design. His design focused on being lower but shallower sides and he created a good base. Meanwhile I focused on a funnel with steeper sides and despite the cup having to be lifted higher I think the the speed of the steeper funnel will counteract that. Today also marked the start of club expo, we drove winston around and put the flag in him to make him majestic.

Today the JPL group broke off again. Alvin created kevin's base that he designed and also created the receptical base. They then found a piece of particle board and traced out the lines for kevins's funnel. Cole and I continued refining our design.

Today a group of went on a field trip to GCC... no, not that GCC. Glendale career center GCC. It was for an event called glendale tech Week. A group of us went down to show off our skateboards to try to fundraise. We were stationed in front of the alex theater and we spent most of the day just riding skateboards around having fun. A few of us went in to see some of the talks that happened. We got served food from someone on 696 which felt good. Lucas brought exploding kittens which was fun. All in all, a great day.

Today the JPL group broke off again and Ian, Kevin and I cut out the pieces for Kevin's funnel design and then Alvin duct taped it together. It fit kevins frame well. However there were a few problems, th fish didn't fit through the bottom at all angles and it didnt always go to the bottom.

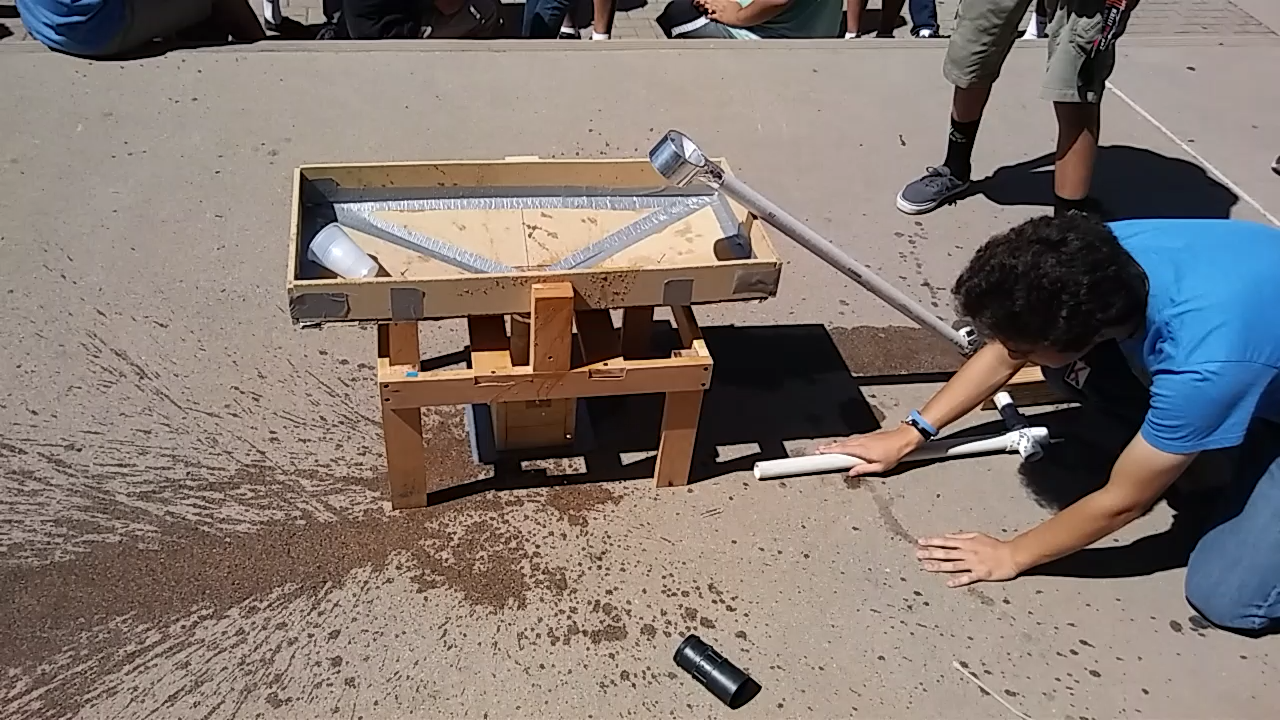

Mr. Wilton wasnt here today but at lunch I learned Dr. Neat wanted a rough working concept for any way to get the water into the funnel. I tried to work with my concept. I used angled steel and aluminum, a furniture mover, some bungee and enough bungee to hold the US together if Donald Trump gets elected. We then had a competition which no one won becuase we were all disqualified for one reason or another. I discovered that inertia may cause a problem for me when picking up the cup so I'll have to figure out how to compensate for that and make sure it isn't an issue. I also learned even if your design is a mess and it doesnt work at all like intended you can have lots of fun and learn a lot. No one ever learned from not failing.

Today the JPL team split off and Cole and I continued to refine and work on the cad and design for the overhead crane. We are finally starting to see the finish line for the cad but we have a long way to go. Alvin cut my funnel design out of cardboard and lined it with packing tape to seal it. Over the Weekend justin contacted me about a reason to get the cnc(last year's senior gift) up and running. He needs some pieces for his electric longboard that need a cnc to be made. I proposed to Neato and Mr. Miller my plan and kevin and i got approval to work on it during our free 6th period. What happened after 5th can only be explained in one way: you have never seen so much work done with absolutly no result in anything. We were struggling so hard and working at it for so long, but there was absolutely no progress at all. We installed a few programs...

Tuesday Cole and I continued working on the CAD still and refining it even further. We worked out a last few major flaws that we saw and had a lot of discussion of possible ideas. After school yesterday i did some research and made some advances at home with the CNC. Then today during sixth period we actually got the cnc moving and doing stuff, sadly we couldn't cut anything because there wasn't a teacher to supervise us. But i was very happy.

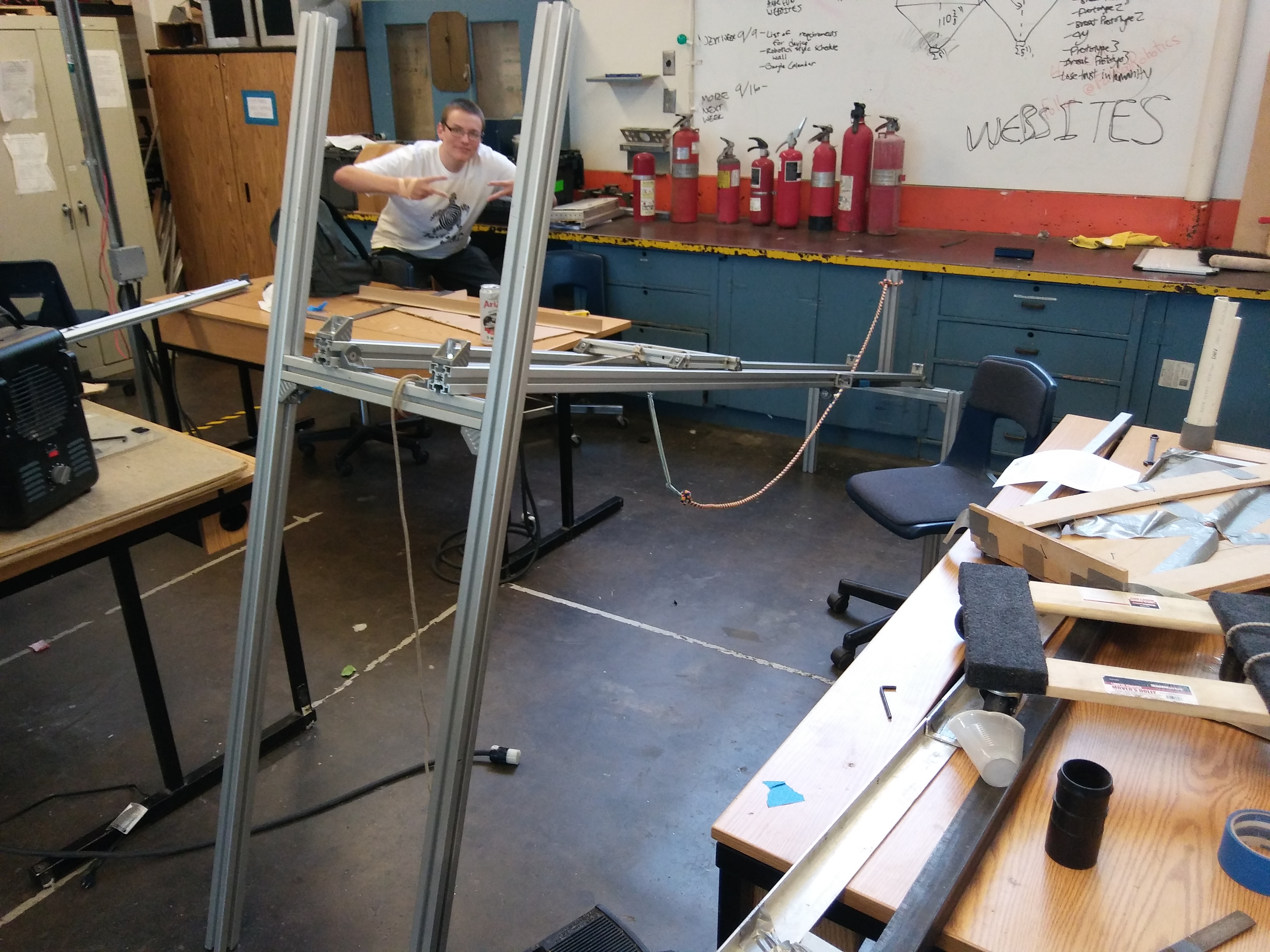

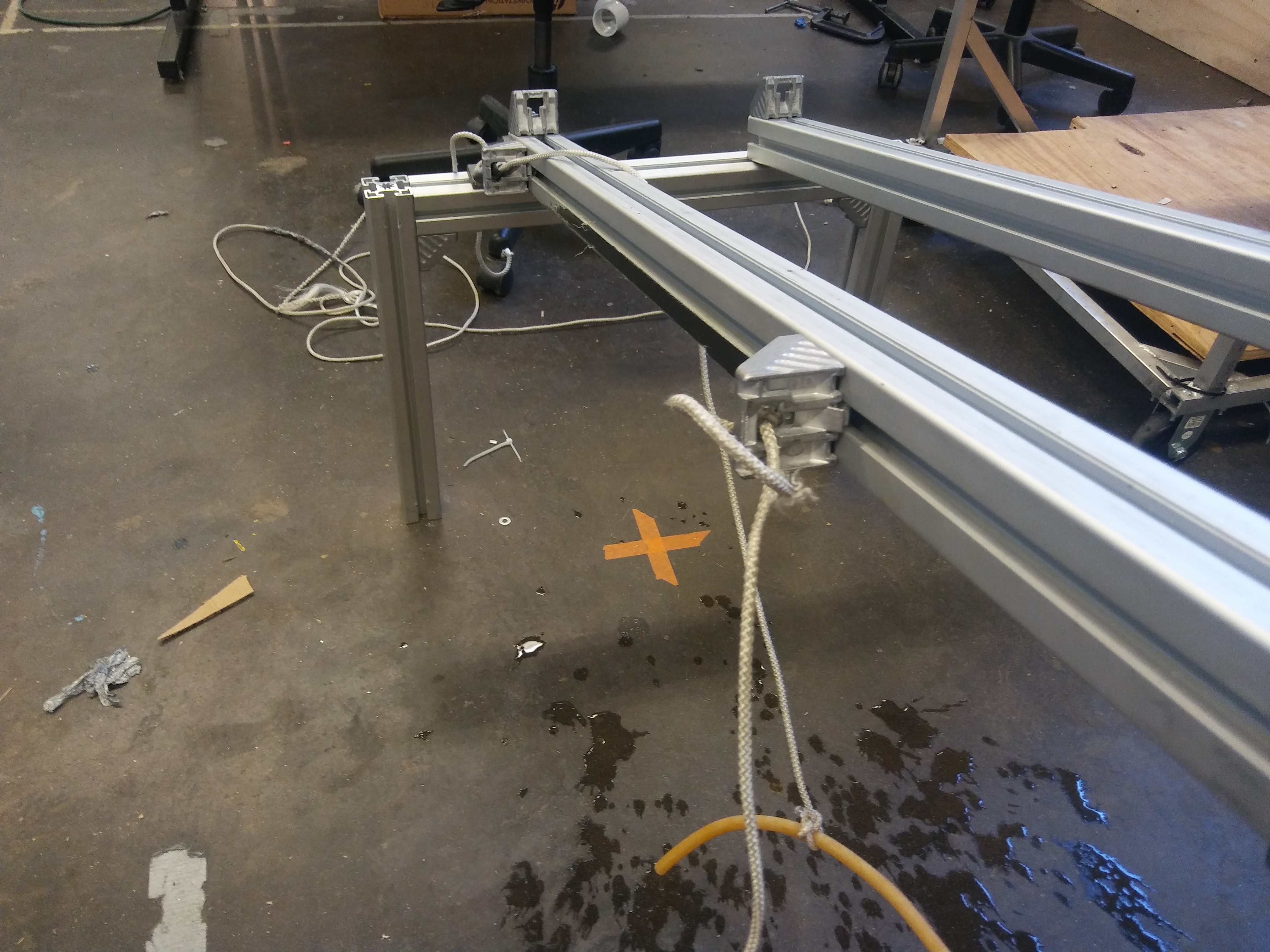

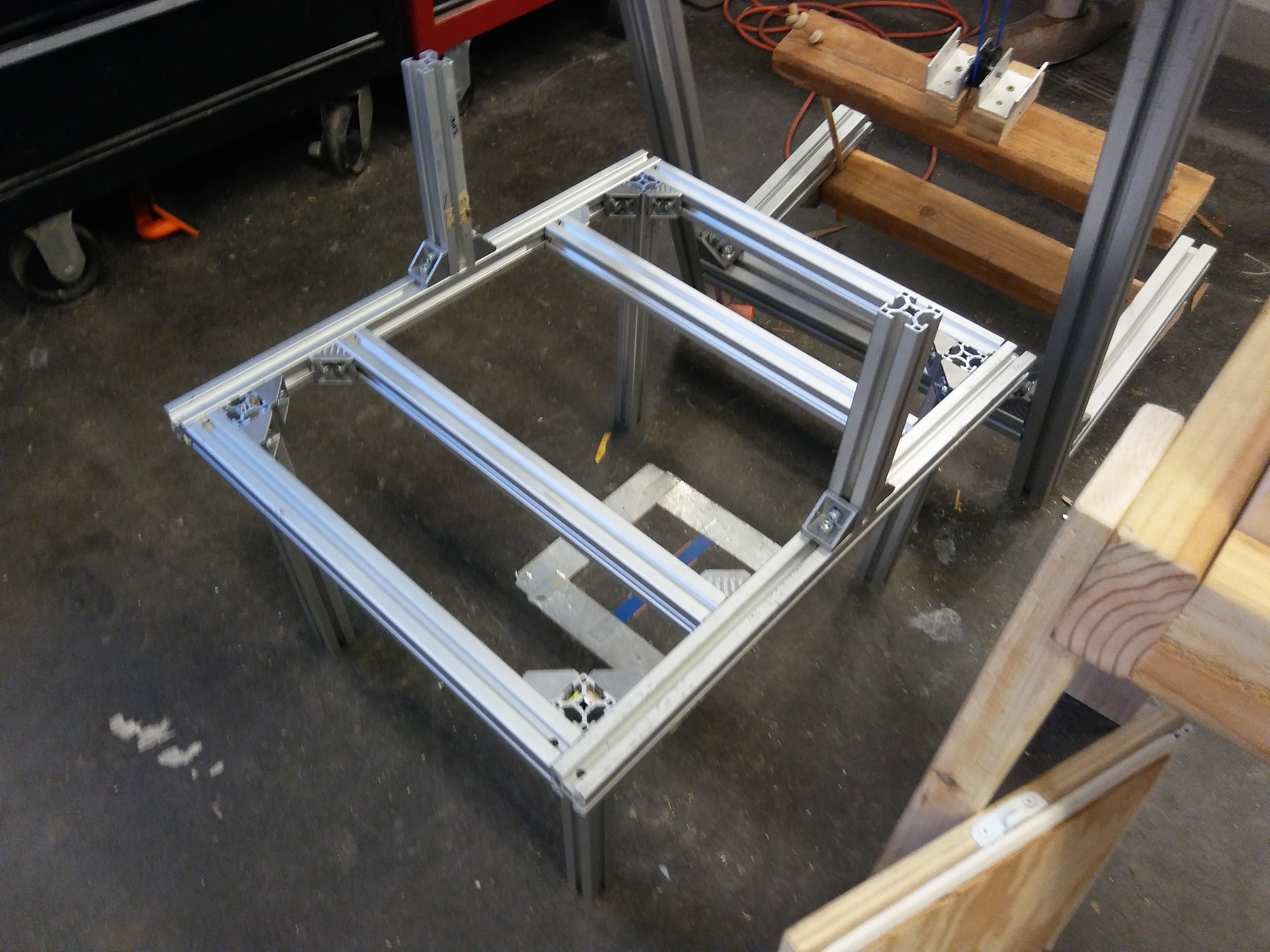

JPL group broke off again and since most of the other groups had started creating physical concepts Cole and I decided to start as well after a little bit more cad work. We used the x-bar stuff we have and we made a very crude model of our cad and did a little bit of testing, the results were very promising. We're utilizing a pure sliding mechanism for our concept but this will change. I forgot to take pictures, but i promise it looks really cool.

So JPL broke off again and Cole and I furthered our physical concept. We got it to a near working phase and adjusted the CAD to account for a few problems we discovered in making the design. It was very helpful and we learned a lot from our simple concept. We haven't decided if we're going to use the x-bar on our final design yet.

Wilton and stuff, lots of good ideas no pictures(i be dummy). Will write more when im not tired and sick.

Today Cole and I worked on the cad again and added more of Mr. Wilton's ideas. WE focused on our tipping mechanism and the way we're powering it. It is comming along fairly well but we're still behind

Today Cole and I furthered our frame implementing a simple tilt mechanism. We noticed that our slider is starting to have a few problems so we need to start serously thinking about wilton's idea of wheels.

I Cole and I just contiinued to work on our CAD and the frame. We made improvements and made our slider better.

Today Mr. Wilton Came and we presented our frame. WE got some god feedback and ideas that we will implement next Week. Cole and I need to have a discssi9on about how we're goign to power it, with a mmotr, or a bungee.

Today Cole and I discussed the use of bungee vs a motor to power our system, we discussed and at the end we sort of agreed upon using bungee as our powering method

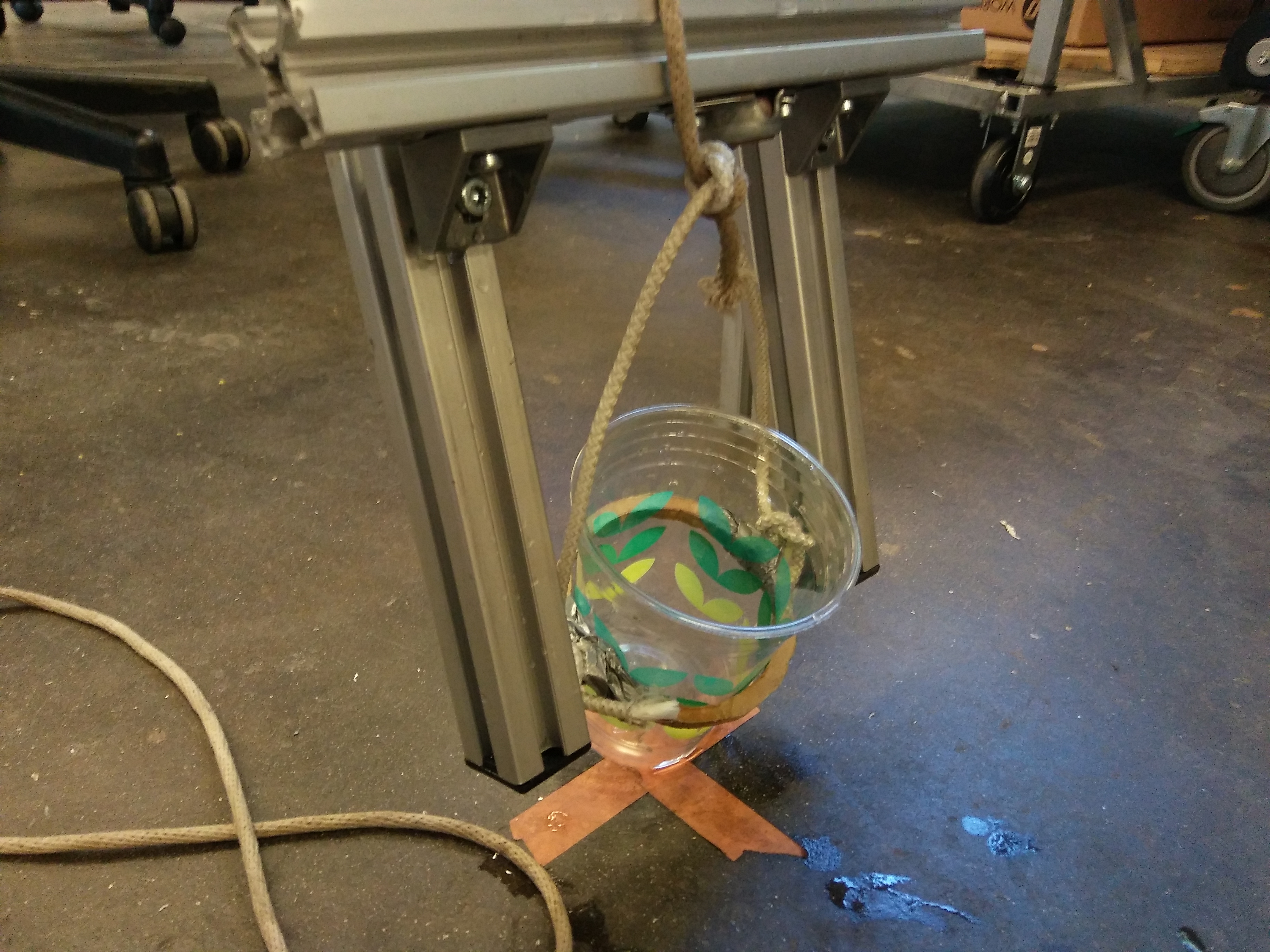

Today Dr. Neat started the peiod by showing us a video of Boston Dynamic's Atlas robot, it was pretty cool. After, Cole and I implemented the lifting ring and the knot to stop it. We hade te ring our of hardboard and duct taped two small bars onto it so that it can slidw and also rotate to pour the water out.

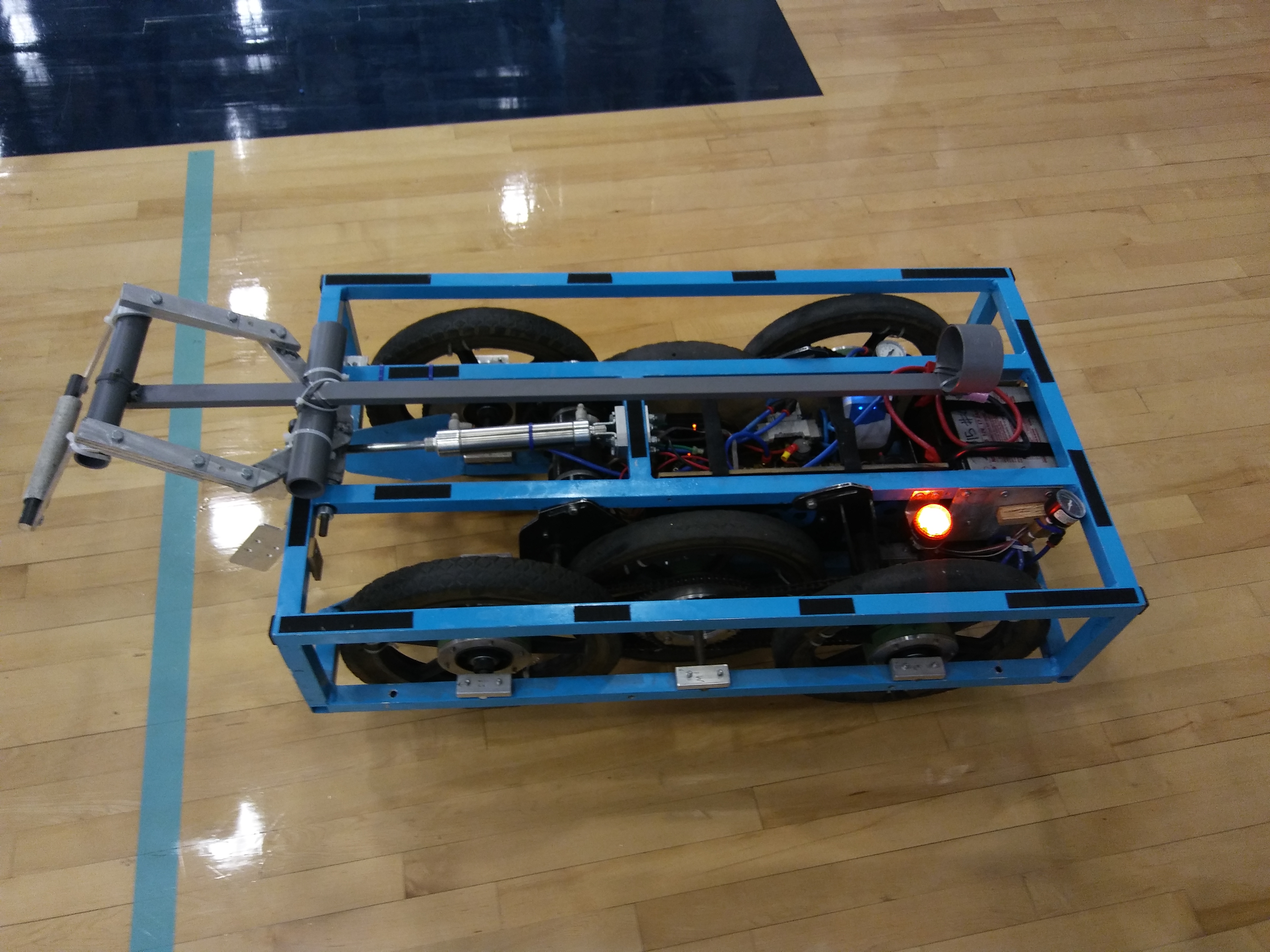

Today was the homecoming spirit assembly, since lucas was on the court we had winston take the flower to him. I was the driver and it was a lot of fun to miss three periods for a minute of driving a robot. And in class I worked on making some 3d printed wheels

Today I brought in a 3d printed wheel to show Cole and do some test fitting, it worked well so we're goign to go forward with the idea.

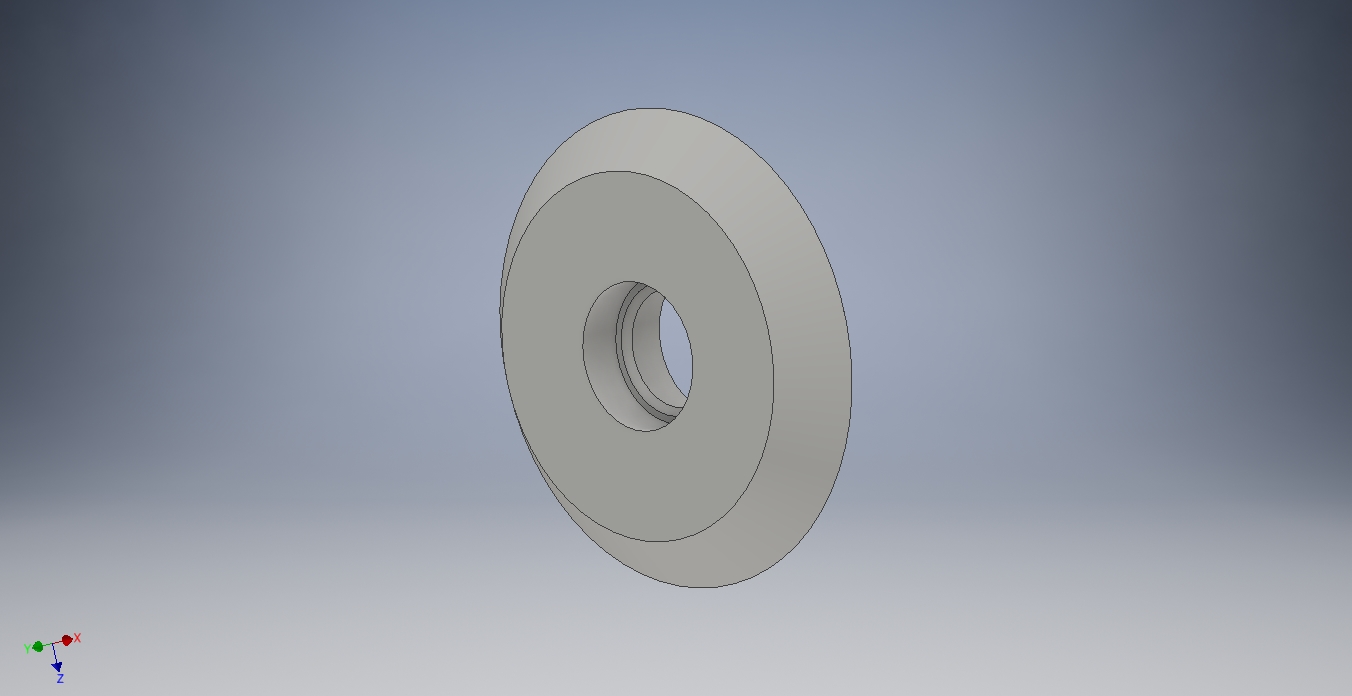

A cad of the wheel.

A cad of the wheel.Today Mr wilton came again and we presented our progress on the frame and we showed them a wheel to give them idea of what it looked like.

Today I brought in more wheels however there was a problem with the printing and they were generally pretty poor. Cole and I were able to start thinking about positioning and how we would mount them. Since we had agreed on using bungee I also designed a pulley so that we could get a distance multiplier out of our action.

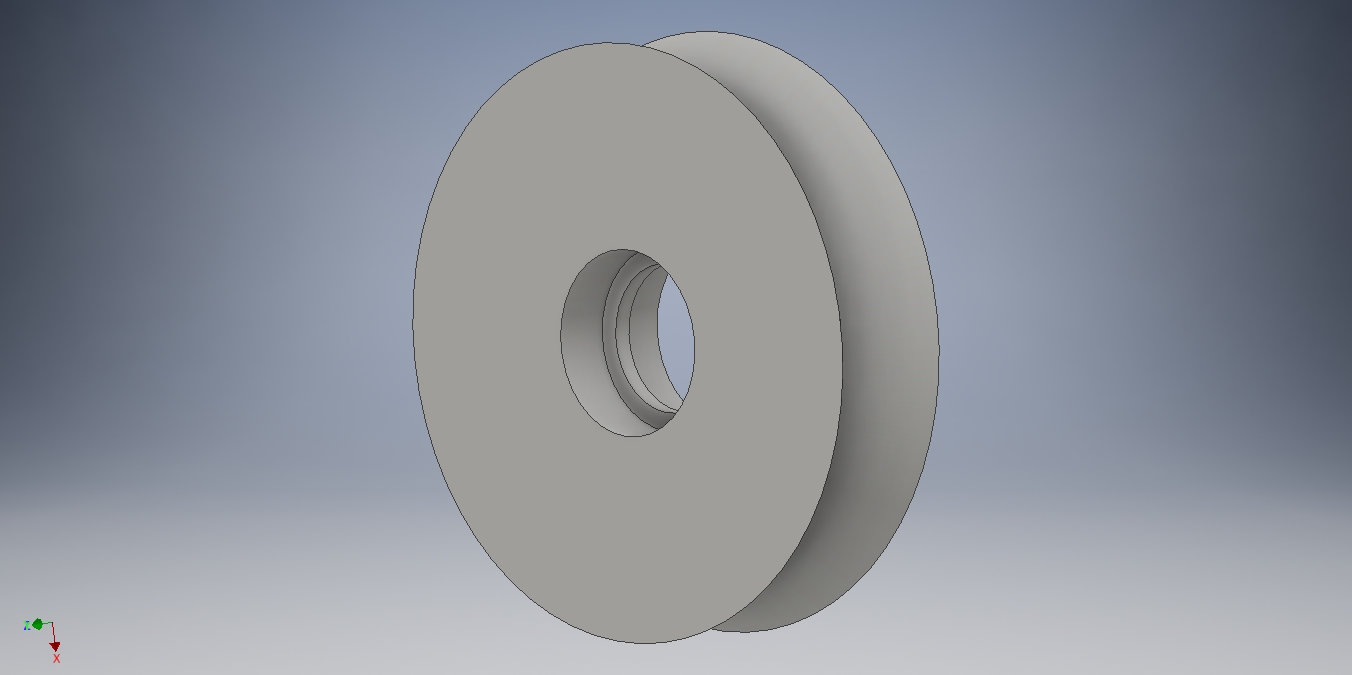

A cad of the pulley.

A cad of the pulley.Today Cole and i did some adjustment to the cart to make sure that the wheels would work. After school I went to a surplus store called apex. If we had gotten the bearings from mcmaster carr it would have been over 100 dollars but from apex we paid 20 dollars for 20 bearings.

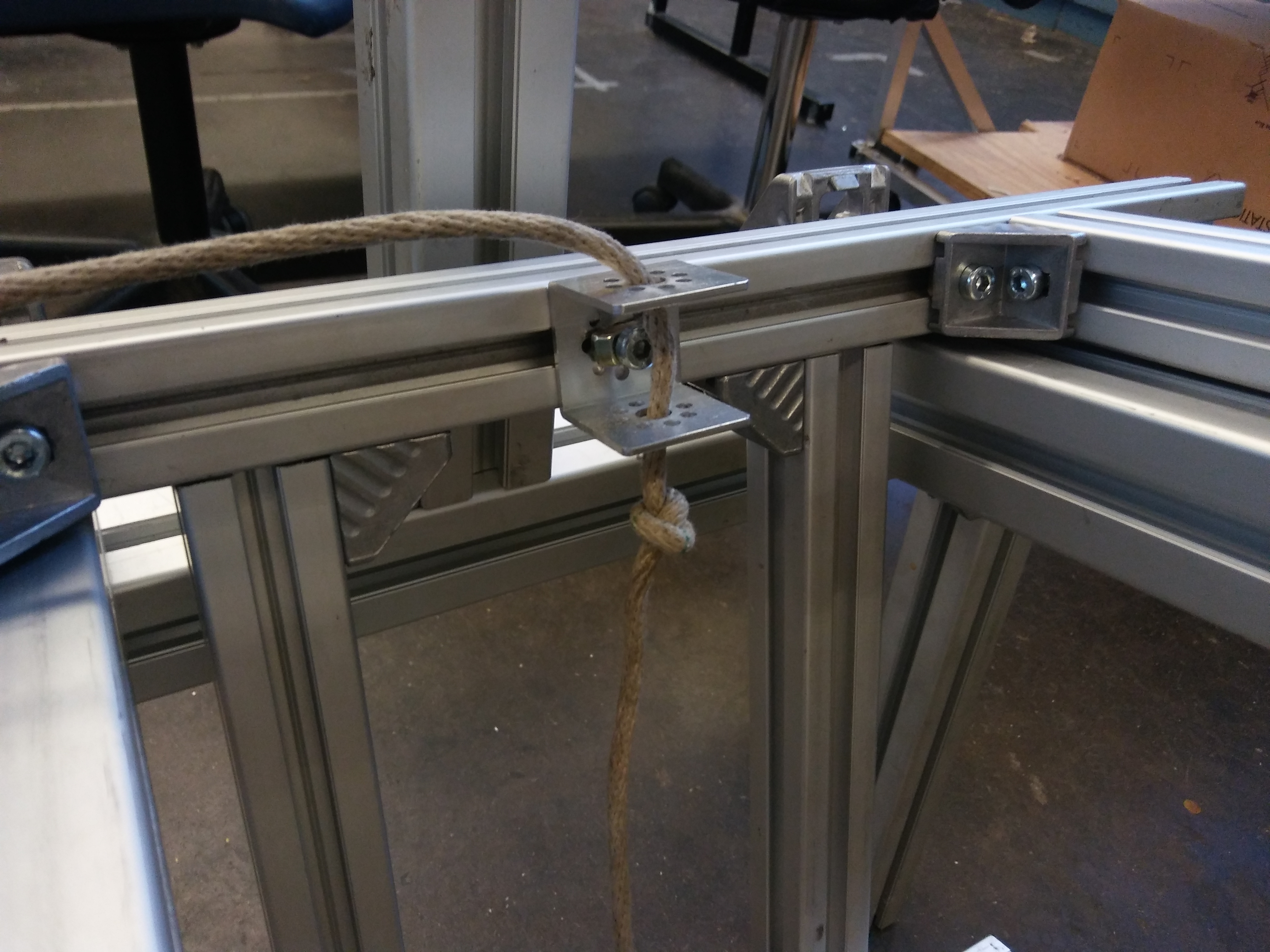

Today Cole and i mounted the bearings into the wheels and the pulleys i printed and we started mounting them to the machine. After school i printed better wheels so that they wouldnt fall apart.

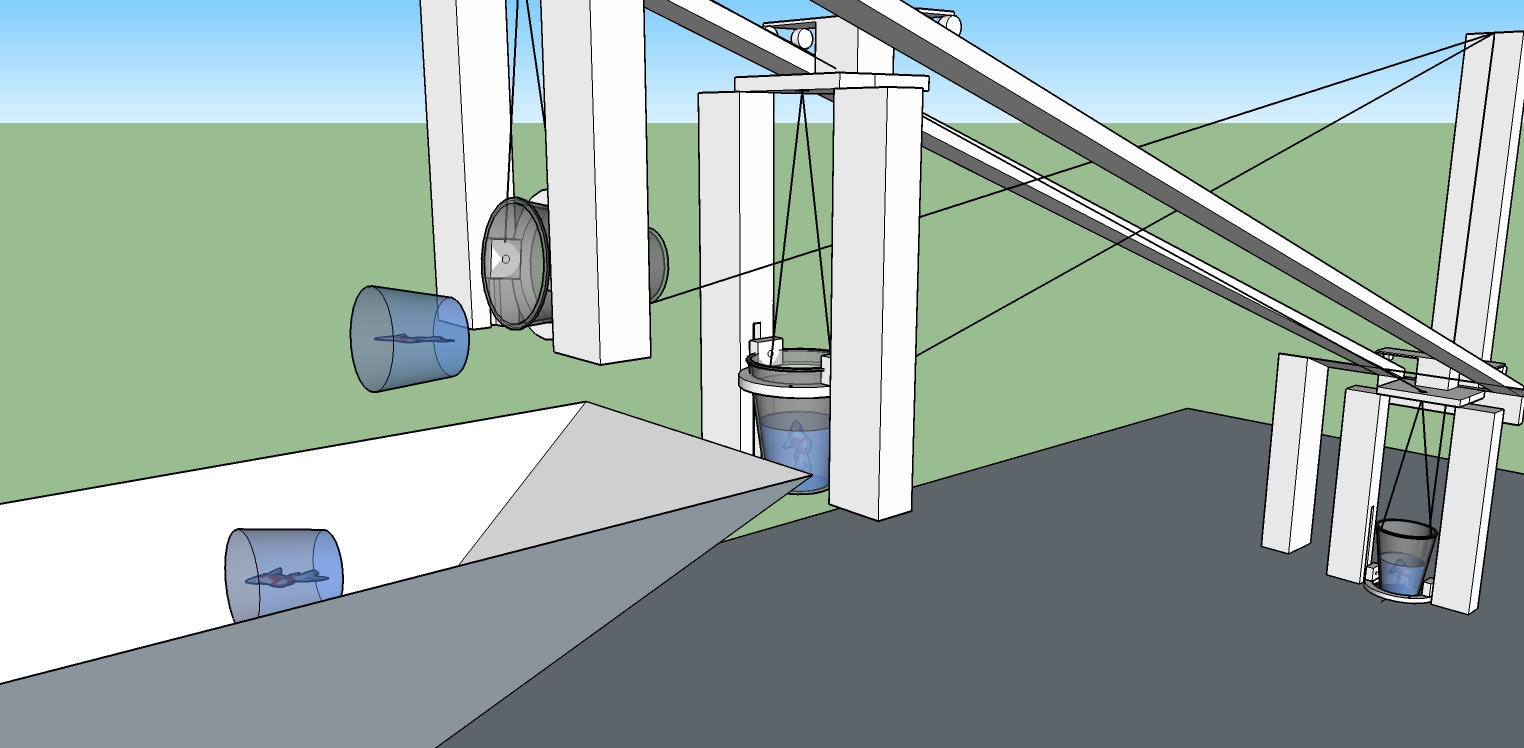

Today Cole finished mounting the wheels and pulleys and i created the power mechanism. For the wheels we have four on top and four on the inside of the track so that it doesnt fly out and cause problems. Today after school we had our first test run, it sprayed water but having a working prototype is a bit step forward for us.

Today Cole and I presented our prototype to the class and Mr. Wilton and showed them it working. Mr. Wilton was pleased, he still had more ideas including a breaking mechanism which we used but seeing him happy with us was a great freeling.

Today Cole and I tried one of our new ideas we got from talking to Mr. Wilton, we started to implement a breaking mechanism to slow down the cart before the very end, so the violence of the cup tipping is reduced. We got most of the way there but we realized that it would actually pull the cart backwards a bit after and so we started work on a latching mechanism to keep the cart at the top when it reaches the end so the water has time to pour out.

Today Cole wasnt here, I worked further on the braking and latching mechanism. I made it out of stronger wood and adjusted the shape so that it works, its very close but we need to add in a spring mechanism so that it gets pushed down onto the cart and can catch it. I have an idea for this and will see what Cole thinks of it tomorrow. I also did a bit of work on the cart itself and tightened the tolerances on the weheels so hopwfully it will roll better.

Today Cole and I installed bungee on the latch to make it grab the cart better and more reliably. We further adjusted the braking system to work better with the latch so that the cart barely goes past the latching point, reducing the amount of spill.

Today cole and I improved the lifter ring, we added a bolt to the front which we can attach a rope to so that it tips a lot better, a lot less violently, and more reliably. We did more tests and we're getting a lot more water now but we're still losing too much. Here's a bunch of pictures of stuff we did.

Today cole and I did more tests and our bolt that we put through the ring brooke off so it was finally motivation enough for cole and I to work on a metal version. So we spent today designing our metal version.

Today we started work on our ring, we decided to use kevins pipe but to also lathe out an inside portion so that it would grab the cup higher up like we needed. I started work on the bolt holding blocks.

Today cole and I finished our parts and decided to weld them together which went pretty well, we got everything very close to being straight(ish). Since we were welding kevin also had us repair his ring since it broke off due to some bad welds by people not to be named.

Today cole and i installed our new ring and did some tests which went very well and the ring held up to the abuse we subjected it to.

Today Mr. wilton came in and we showed off to the class our progress but our test was ruined by the start so after class I made a quick release that would be more reliable and consistent. He gave suggestions for us to make our own funnel and to slow down the initial jump of the cup to reduce water loss.

Today, in order to try to reduce the initial shock which Mr. Wilton was talking about I put on a length of bungee in the rope and which will hopefully slow down the initial acceleration causing less water loss. We also replaced the rope with paracord which is a lot more robust.

Today I started on a water retention system that would keep the cup level for the first portion but still allow it to tip at the end pouring out the water. It also slows down the initial jump causing less water loss. I also changed our rope attatchments for the brake and tipper so that we can now adjust them by sliding the rope attachment points.

In order to further our water retention I added some cardboard flaps in order to try to reflect the water back into the cup and make it better, but by the end of the day the cardboard was falling apart so it wasnt a good idea.

Today, I replaced the water retention meechanism with wood so that it doest get soaked and destroyed. Today cole also got started on a new funnel, he started cutting the pieces for the base and soon we will talk about what we want our actual funnel shape to best fit our design.

Today Mr. Wilton came in and we showed off a really good run of our machine, really close to being competative at the competition. We still lost some water which was wiltons main focus but he seemed pleased with us which was good.

Today, I tried to make a few more improvements on the water-keeper-inner by tightening some of the tolerances and making it more repeatable, I also got rid of excess rope and bungee so that we're closer to not touching the cup at the beginning. Cole continued to work on the base of the new funnel, he should finish the base tomorrow so we can have a discussion about the new funnel's shape. I also printed some new wheels that we can coat in resin to make them stronger and work better.

Today Cole was sick so I finished the stand for the funnel and started thinking about what the funnel itself should look like but its hard without him to brainstorm with. I also made an adjustment to the water-keeper-inner that I think will improve our water retention bigly; though i didn't get a chance to test since we dont have our funnel. Hopefully tomorrow we can get the funnel cut out and assemble it at lunch thursday to show to wilton. Fired up, ready to go.

Today cole still wasnt here so I just spent the time creating a CAD of a possible funnel design and emailing it to him to get his thoughts on it. We ended up with a design that will fit our device much better and will be a much more efficient design. As you may be able to tell, we didnt get it cut out so we will have to do that monday since wilto is coming tomorrow.

Today cole was finally back, I showed a CAD of the new funnel to Wilton and the class and they approved, we also did a really successful run of our device with very little water loss. We dont have much time left, though luckily we just need to get that damn funnel done. I really hope we get it done and do well, though, if it really comes down to it we can use the cardboard funnel which is a bit of a reassuring thought but i want to avoid that as much as possible.

Today Cole and I finalized our funnel cad and during class we marked out all the lines onto scrap plywood we had. After school I got some brackets at osh and came back to school to cut out the pieces. Cole and I got all the pieces cut out and attatched two sides together which is a good start.

Today at lunch Cole and I went in and finished assembling the funnel. The main construction was brackets holding it together and we ended up having 64 screws sticking through the sides. We then realized some of the screws could possibly catch te fish so we cut some of them down so they didnt stick through. Then we caulked the funnel and then rested it in the base. We had a lot of down time since we couldnt do anything while the funnel was drying which wasnt good, i wanted to be doing tests but we would have messed up the caulk if we had gotten it wet. I took the time to start working on the cad for the insert we're going to use and then tonight ill print it. Tomorrow we'll attach the insert and afix the funnel to the base and then we will test like there's no tomorrow.

Today us and kevins group started experimenting with a hydrophobic material that we can put on our funnels in order to have the water run off better and get less soaked into the wood. Kevin did most of the testing with that while cole and I did testing with our whole contraption. We are initially pleased with our results but we think if we use kevin's hydrophobic stuff we could do a bit better. After school I put on some hydrophobic spray so that it can dry overnight in the hopes that tomorrow we can just test and test. THis project has kind of consumed my life, I just realized i didnt have anything to eat today except for an apple... Im going to go eat now.

An example of the properties of the hydrophobic material

Today has just been as much testing and small improvements as we can. Tomorrow will tell us who even goes to the playoffs. We were doing well but then our performance started to drop and we started to lose more water than we had and we're not sure why. I think we just really need to adjust our tipping mechanism and our water-keeper-inner. I hope with those adjustments early tomorrow we can do better than we were today. I'm starting to get pretty damn nervous, its a lot of work at stake, tomorrow will be a time where there is only work and nothing else.

This is essentially our final desing for the test tomorrow and playoffs.

Today was the day for us to show off and to see who is going to agustus hawkins tomorrow. We did a mock JPL with timed setup and everything. Cole and I ended up winning because we only lost enough water for a 5 second penalty while kevin lost too much so he got a 15 second penalty. Though after school I did some more adjusting and got some near perfect runs. Im optimistically cautious.

So today was the JPL invention challenge, we go here early, packed up and then headed off to Agustus Hawkins high school, I rode with cole in his truck with our device, we very nearly clippid the parking grarage with the top of our device. We waited a lot, then it was finally our turn, we set up, waited for kevin to go, and then we launched our device... Sadly, the tipping rope wrapped around the trolley and it didnt make it all the way, we didnt get any water into the cup nor did we get the fish. We were dissapointed and then we made a slingshot and launched stuff, then we launched each other with a football thing. I was upset.. but ya know, it was fun. Some good lessons learned for the future.

Today we learned we are going to perform a presentation about jpl, what we did at the competition and what lessons we learned. We all added our own stuff to one presentation. I spearheaded the effort and by far cole and I had the best slides, I also took my camera to JPL and got a lot of pictures and so i plan to show those off as well.

Today we presented, it was kind of a trainwreck, no one took it seriously. But towards the end it actually started to get okay we talked about our lessons that we learned and got some real deep life lessons as well. I was the driver for the presentation and really was the only one who really cared so Im happy it ended up going well in the end.

Today Dr neat asked us who have our websites updated to help run the wednesday challenge. The other veterans went to work on their websites. So it was kevin, alvin, and me working the challenge. The challenge is to CAD a structure made of marshmallows, grahm crackers, and pretzel sticks. THen they swap CADs tomorrow and they will build it from the cad. The main goal is height but if it's inaccurate then the team is automatically disqualified. So our job is to track data and hand out the materials, tommorow we will measure and be the judge of accuracy.

Today was the building day of the Wednesday challenge. It was a mess, there were problems with file versions and limited supplies and CAD's that were impossible to build. It was stressful being in charge. In the end kevin and I decided to disqualify 4 teams. These are the results

Today Mr Wilton came in one last time so we could discuss our lessons learned. We all sat in a circle and went around with each of us saying what we would repeat, what we would do differently and how many hours we think we put in. I would repeat working with Cole agin. He and I think very similarly and that allowed for us to just work with less talking and get done what the other wanted. One thing i would do differently is plan out our changes, a lot of times we scrambled to just get things done and often resulted in harder problems for us later. We also learned that for the final wednesday challenge it would be the JPL invention challenge and if you beat kevins device then you get an A.

Today we worked on our device and we thought of a new way to place the brake line in order to make sure it doesnt get caught. We also tightened soem of the tolerances and tightened the bungees. But we noticed our funnel attatchment was now our major loss of water and so we decided to design and print a new one similar to kevin's.

Today, cole and I did more final tests of our device to see if there were any other major improvements to be made. We also talked about the specifics of the design of the new attatchment

Last night due to scheduling conflicts i couldnt print out the new attatchment so we decided to adopt the one from kevin's device. He doesn't need it any more and it fits right in our funnel. Since jacob took his caulk home we hot glued it in place. And now theres very little water loss.

Today I joined the group working on shortening the tables for the cad group in robotics. THey want to re-arrange the room but they need the tables shortened so we are taking off the cable boxes and cutting the excess off and moving the legs forward.

Today I did a few more tests of my device to see how its holding up and then did more work on the tables, we're startin to get it down and im becoming pretty good with the grinder which i didnt have much experience with before.I'm happy to be doing helpful work and learning at the same time, its also good to get back into steel welding.

Once again I did a few tests at the beginning of the period in order to make sure the machine still does well so that i get that A in the class and on the final. After that i did some more work with the tables, we've started to get into a routine, we finished the first table and started the second one today out of 4 tables we need to do in total.

Today, I actually didnt do a test, due to time constraints we need to try to get the tables done as soon as we can, i think giving the machine a day of rest is also a good idea. We finished the second table and barely started the third one today.

Today we got most of the way through the next table but it didnt go as fast as we had becuase of problems with the grinder and the cutting disc becoming too small so we need to get a new one of those. Im getting better at steel wlding again, at first i kept punching through since it had been so long but im getting better again and learning the importance of using the right settings in welding.

Today was finals for periods 1 and 2 so i didnt have engineering. It was my physics and econ finals. I know i did well in physics and i feel pretty confident about econ.

Today was finals for periods 3 and 4 for me they were math and english, both pretty easy finals and i did well on both.

Today is the last day of the first semester. It was the engineering final which means our device got a second chance. But, of course, murphey and his laws came in again and we had another failure. That sucked but hey, stuff happens. The rest of the day we worked on the tables and got them almost completely done. Cole and I will come in one day over the break to finish those.

If anything seems familar to you, I refer you to this video Tom Lehrer, Lobachevsky